Production equipment

JSC “FED” is equipped with modern precision production equipment of world brands.

Turning machine cluster:

Spinner (Germany)

Weiler (Germany)

Doosan (South Korea)

Star (Japan)

Emco (Austria)Spinner

Turning equipment is represented by ultra-precision machines Spinner with a tolerance of the measuring system of 0.1 that allows performing high-precision processing. The machines are used to process tempered parts with a hardness over 60HRC and the maximum diameter of 120 mm and 400 mm. The machine has the back spindle and are completed with the robot manipulator that allows manufacturing complex parts in one operation in automatic mode.Star

The Star machines allows manufacturing parts in fully automatic mode. They are intended for mass production of parts with high accuracy.Doosan

Doosan turning-milling centers allow processing of large-sized parts with a diameter of more than 450 mm and a length of more than 670 mm, performing a variety of complex milling and slotting operations, including cutting and slotting of ring gear and slot.Milling machine group:

Spinner (Germany)

Hermle (Germany)

Picomax (Switzerland)

Kovosvit (Czech Republic)Picomax и Spinner

Milling equipment is represented by 5 five-access machines Picomax and Spinner. Due to the capacity of the working spindle, they are suitable for both rough grinding and high-precision finishing up to 0.003 mm. The turning rotary table allows processing the most complex configuration of body parts.KOVOSVIT

KOVOSVIT The KOVOSVIT vertical machining center is used to manufacture large-sized precision parts. The machine is intended for accurate and high speed processing of complex surfaces.Grinding machine group:

Kellenberger (Switzerland)

Studer (Switzerland)

Reishauer (Switzerland)

Micromatic (India)

Klein (Germany)

ZSS (Germany)Studer и Kellenberger

Precision grinding machines Studer and Kellenberger are used at the production facilities. Since the control of axes is performed in the nanometer range, precision is achieved with an accuracy of up to 0.0001 mm. Interpolated rotation of the head spindle allows grinding the part with complex surface shape and produce high-precision conical parts.Spark-erosion equipment group::

Sodick (Japan)Sodick

Spark-erosion equipment is used to process very hard materials with obtaining of high quality of cutting with an accuracy of up to 0.001 mm and roughness of up to Ra 0.1. Spark-erosion processing allow solving the most complex technological problems and handling parts of complex configuration. The big advantage is the absence of risk to deform thin-walled parts.Superfinish equipment group:

Gehring (Germany)

Sunnen (USA)

Stahli (Switzerland)

Thielenhaus (Germany)

It is capable to refine the geometry of both internal and external surfaces with an accuracy of up to 0.00025 mm.

Flushing is performed at the following installations:

BVLMosel (Germany)

Crest (USA)

VACUUM-CAST (Poland)BVLMosel и Crest

To ensure high purity of manufactured parts and assemblies, washing installations BVLMosel and Crest equipped with filtration of particles larger than 10 microns are used.Nanocoating and welding

Site of Special Technology

Technologies based the vacuum-arc application of coatings are widely used in modern machine-building industry, instrument-making industry and other industries due to the ability to form coatings intended for various purposes (strengthening, wear-resistant, protective coatings etc.) with properties that cannot be often achieved by using other methods of coating application. JSC “FED” developed multiple-component, multi-layered, superhard, anti-friction, wear resistant coatings to enhance performance of various parts used in machine engineering and engine-building in terms of wear and fatigue in corrosion environments, etc. On the basis of these coatings, the company developed more than 30 technologies for application of multi-layered low-temperature (≤ 150–200 °C) coatings to improve reliability and service life of friction pairs in mechanical engineering industry.

Coating Avinit C 320 and Avinit C 310 and technology of their application are patented in Ukraine, Russia and the European Union. The developed technologies are introduced into mass production at JSC “FED”. Using of developed coatings and methods of their application allow to increase the service life and reliability of units produced and developed now by several times. For example, the use of slide valves coated with Avinit C 320 in the hydraulic units allowed to increase their life from 50 h to 4000 h. The use of coatings Avinit C 310 in friction pairs of the units increased their resource from 200 h to 2,000 h.

Vacuum hardening

The bay developed and patented technology for application of coatings Avinit C 320 and Avinit C 310 using vacuum-arc method to improve reliability and the service life of friction pairs in machine-building. The use of developed coatings allows increasing the service life and reliability of units manufactured by the company by several times. The use of vacuum plasma precision nitriding allows to obtain a uniformly hardened nitrided layer without deformation of produc...ts while preservation of initial geometrical dimensions of parts with an accuracy of 1.2 microns that allows avoiding finish grinding. The available complex of automated equipment for vacuum heat treatment allows implementing high-treating technologies, quenching with the use of gas cooling, tempering, and low-temperature treatment.Ion-plasma material surface treatment Avinit (Е)

The installation is intended for experimental elaboration of new technologies and improvement of the existing technologies of ion-plasma material surface treatment in plasma of high density glow discharge initiated in hollow cathode. The installation ensures the possibility to process material surfaces in high density glow discharge plasma in gaseous media of different composition (argon, nitrogen, carbon-containing gases and mixtures of these gases), including inte...rnal cavities and channels of the certain size. The use of high density glow discharge plasma in the processes of ion nitriding, carbonitriding allows reducing the times, as compared with gas furnace technologies, required for formation of hardened layers with a thickness of 0.3–0.4 mm, while maintaining almost the same size of the processed products and preventing the formation of brittle phases on their surface. Therefore, the development of new technology for surface treatment in high density plasma is one of the topical areas of improvement of the modern technology in some sectors of industrial production.Magnetron application of Avinit (М) coatings

The installation is intended for experimental elaboration of new technologies for application of coatings made of conductive and non-conductive materials with RF-magnetron target sputtering. The installation ensures the possibility to apply coatings of different metals and their various compounds, including non-conductive ones and non-metals (carbon, PTFE, etc.). This allows using the installation for obtaining various coatings that are intended for various purposes...(protective, strengthening, wear-resistant, optical and other coatings) and have different composition and structure (mono-layered, multi-layered, including nano-layered and nano-structured one). Due to this diversity of coatings, the method of RF-magnetron target sputtering and technologies based on its use are among the most popular ones in many areas of modern production and development of new types of coatings and technologies of their production.Plasma chemical vapor deposition of coatings (РЕ CVD) Avinit V

The installation is intended for experimental elaboration of new technologies for applying metal and metal-carbide coatings based on molybdenum and tungsten by decomposing their carbonyls. The installation ensures the possibility to apply coatings with high uniformity in thickness on the surface of products with complex profiles, including blind holes and channels with L/d ˃˃ 1, where L is the channel length, and d is diameter of the channel. The gas-phase method us...ed for application of coatings is the unique method surpassing all other methods, including methods of electroplating of coatings. High hardness of molybdenum and tungsten, in particular their compounds with carbon, nitrogen (carbides, nitrides), high wear resistance and low coefficient of friction of these compounds during work in different pairs of friction and some other properties of these metals allow including coatings on their basis to a class of materials that are has the potential of using in various units and aggregates of modern machine-building, aircraft engineering and other fields of technology and production. Taking into account that molybdenum and tungsten are included in the chromium subgroup and the fact that, according to EU directive (RoHS), the use of “hexavalent” chromium (CrVI) is limited in the production of a long list of industrial products, development of gas-phase technology for application of coatings on the basis of molybdenum, tungsten and their compounds can be in some cases considered as an alternative to widely used technology of application of chromium coatings by electrolytic method.Welding of parts and components

Manual argon arc weldingArgon arc welding with non-consumable electrode are welding is mostly used for connecting carbon steels, alloy steels and non-ferrous metals. For small thicknesses, arc welding can be performed without any welding filler. This method of welding ensures good quality of formed welds, allows to maintain accurately the depth of metal penetration that is very important when welding the thin metal under condition of one-side access to the product surface. Welding with with non-consumable electrode is one of the main methods used to connect titanium and aluminum alloys.Resistance spot welding

This method allows joining both the thinnest parts with a thickness of up to 0.02 mm and parts with a thickness of up to 20 mm that are made of different metals and alloys, and combinations thereof. This method is used to weld wires, rods of round, cross-shaped sections, profiles, sheets, meshes, etc. It is most often used for welding structures made of soft steel, stainless steel, all light alloys and brass. The advantage of this method of welding is related to the...fact that there is no need for welding materials (electrodes, fillers, fluxes, etc.), small residual deformation, simplicity and usability of the welding machine, neat joints (the virtual absence of the weld), and environmental friendliness.Electron beam welding

Electron-beam welding ensures the following advantages as compared to other methods of welding: - welds without shrinkage and deformation of welded parts due to the low heat supply and high speed of welding; - vacuum welding does not only prevent oxidation of the metal in the welding zone, but performs degassing of the weld pool metal; - the possibility to weld a wide range of dissimilar metals with some materials that cannot be welded using other methods; - the...possibility to perform welding in places and positions that are not accessible for other methods of welding through a very small diameter of the electron beam and a considerable distance of its focusing; - electron beam welding is an autogenous process and, therefore, it does not require fillers or fluxes that allows avoiding many of metallurgical problems. Electron beam welding installations used at our production facilities ensures all the advantages of electron beam welding and allows preforming up-to-date high-precision electron beam welding.Equipment of the EEB

The Electrical Engineering Bay ensures the manufacture of sensors and components required for completing products. The bay is equipped with high-tech equipment. The following types of works are performed at the Electrical Engineering Bay.Laser marking

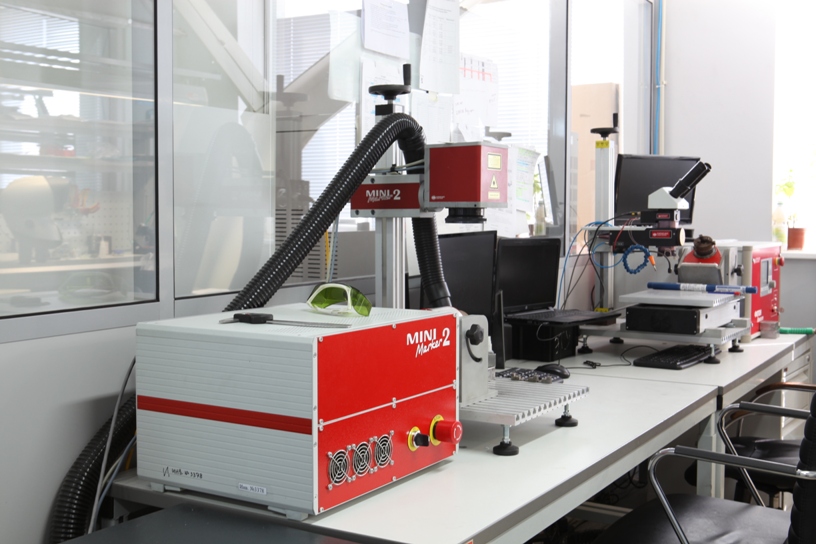

Laser marking is intended for application of text and graphics on the surface of products by laser marking method. Type of beam delivery on the axial scanner, traversing mechanism. The size of active area of processing is 100 x 100 mm. The following materials are marked: metals, plastics, and painted surfaces.Laser welding

Laser welding allows welding of metals, including small details, in manual mode or as part of automated lines. Laser Type: solid state crystal laser operated in pulsed mode.Precision laser cutting

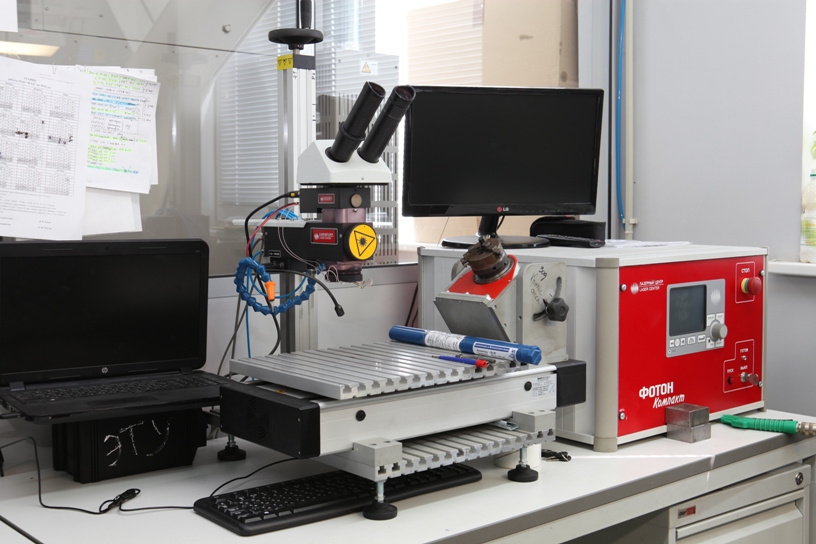

Precision laser cutting is performed with ytterbium fiber laser. Processed materials: metals, alloys, rubber, and textolite. High precision positioning is ±30 microns, and re-positioning accuracy is ±3 microns.Winding of coils

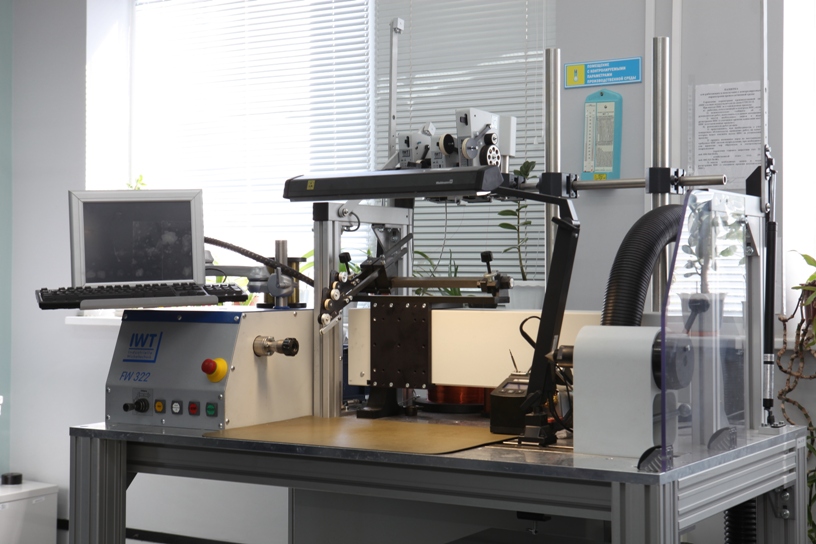

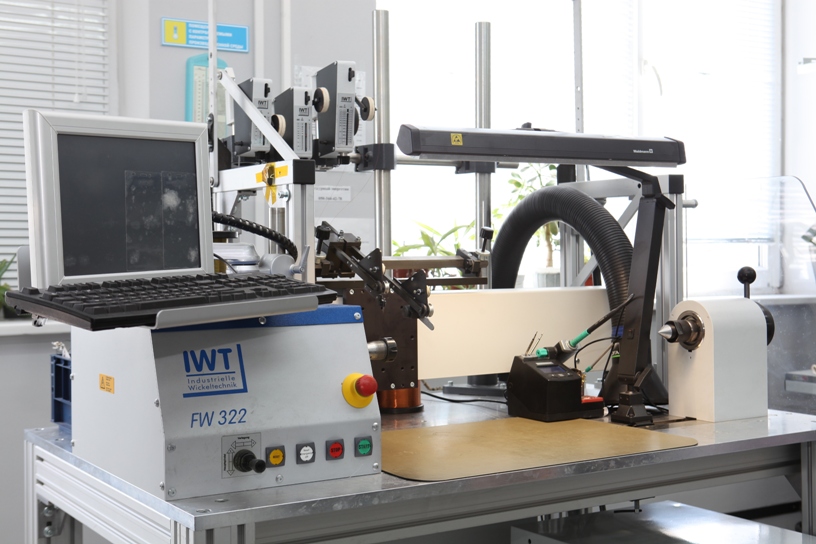

Winding of coils is performed on the layer winding machine — high-speed machine that meets modern requirements of winding production. Easy programming makes it possible to carry out a rapid changeover to a different type of products by ensuring flexibility of the production process. Functional properties of the machine allows to perform all necessary operations: winding of simple or complicated coils, multi-section coils, asymmetric or non-parallel windings. The possibility of storing programs in memory improves performance. The range of cables that can be used for winding is from 0.01 mm to 5.0 mm.Measurement of characteristics with magnet of mild materials

Measurement of characteristics is performed by the fully automatic computerized station. Measurements can be taken on different types of samples: rods, strips, rings, sheets, massive parts, and small-sized samples.Measurement of linear displacements of sensors

These measurements are taken by the special bench intended for testing parameters of functioning of linear displacement sensors by positioning the rod in a given position and measuring electrical output parameters. The bench ensures the possibility of setting the specified voltage, current and frequency followed by stabilization, adjustable load resistance in each section of the winding, the possibility of multi-channel measurements.Testing of products

To simulate environmental conditions and test products for effects of low or high temperatures, as well as for thermal processing and drying of flammable resins containing volatile solvents, low-temperature drying chamber and electrical equipment is used. The range of temperatures achieved is from -85 °C to +300 °C. Unique programming makes it possible to work with cyclic and constant modes. The main feature of furnaces is the capability of drying explosive products.Thermal and Metallurgical Equipment

Induction melting of metals and alloys with a capacity of 100 kg and 150 kg and piston pressure casting

At the production facility, there is bay for casting of high-quality bronze. The casting bay is equipped with everything necessary for high-quality castings by the method of directional solidification and by piston pressure casting.Vacuum heat treatment of components

Single-chamber electric vacuum furnaces with horizontal loading of forced gas cooling of the melting charge are intended for heat treatment of machine parts in vacuum (annealing, stress relieving, normalization) and hardening in inert gas and performance of processes of vacuum brazing and diffusion welding.Component heat treatment

At the production facility, there is a chamber furnace that allows performing heat treatment (hardening, annealing) of a wide range of grades of constructional steel and tool steels in the medium of inert gas — nitrogen. The furnace ensures the possibility to select between the hardening medium — oil quenching and inert gas. The furnace is equipped with a vaporizer for generating gaseous nitrogen from the liquid phase and a refrigeration unit to maintaining a stable...temperature of hardening tank with oil during cooling of parts. Heat-treatment furnaces with forced atmospheric circulation are intended for performing thermal treatment at temperatures below the hardening temperature (tempering, aging, annealing). The bay is also equipped with washing machines for timely and prompt washing of parts from residues of hardening oil.Bench equipment that is in operation at the test facilities of JSC “FED”

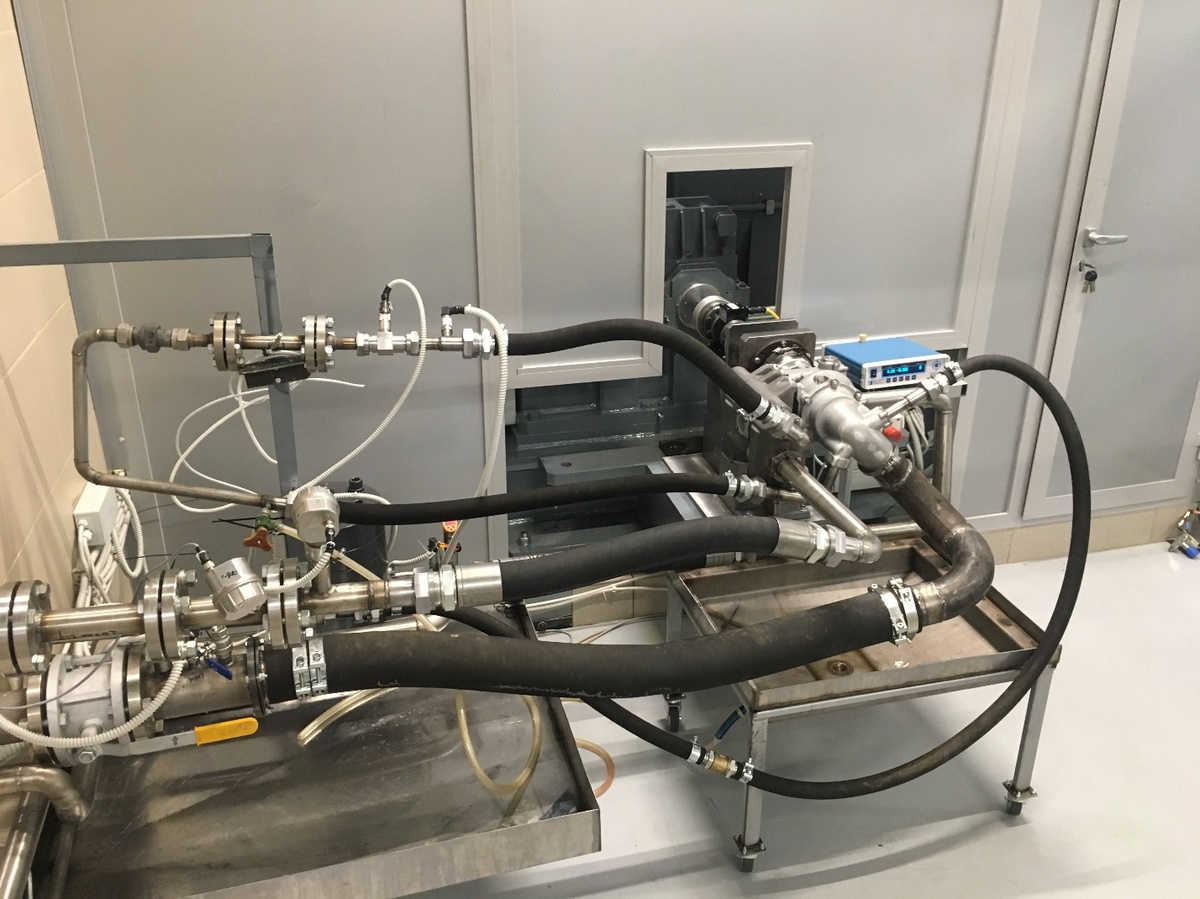

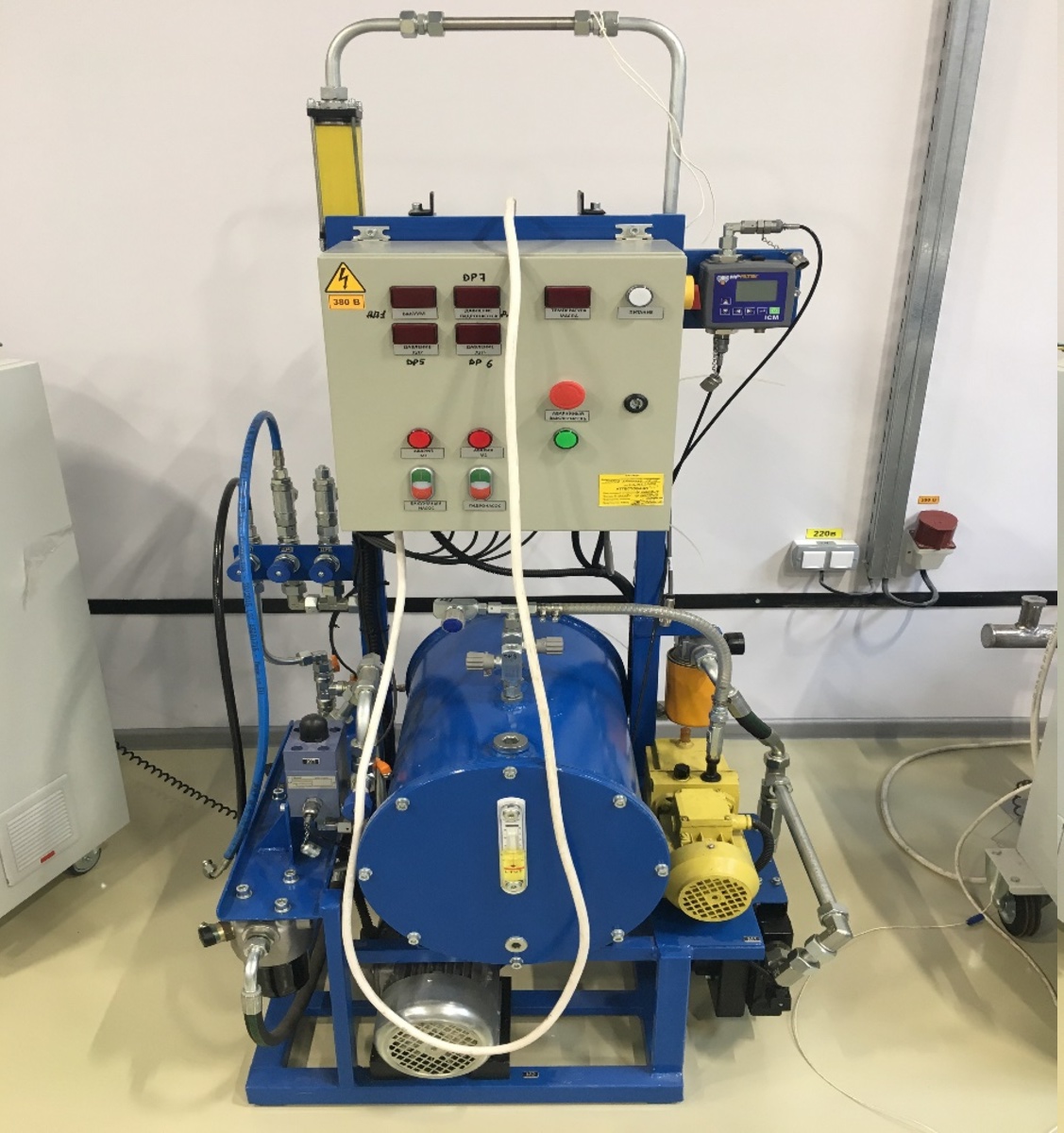

Bench for testing of high capacity regulator pumps

Fuel bench intended for running, adjustment and long-term testing of high capacity regulator pumps. On this bench, it is allowed to conduct testing of units with a capacity of up to 3000 l/min. Power fluid: kerosene ТС-1 or its equivalent. Manufacturer: Test facility of JSC «FED».Benches for life time tests of dosing pumps and rpm governors

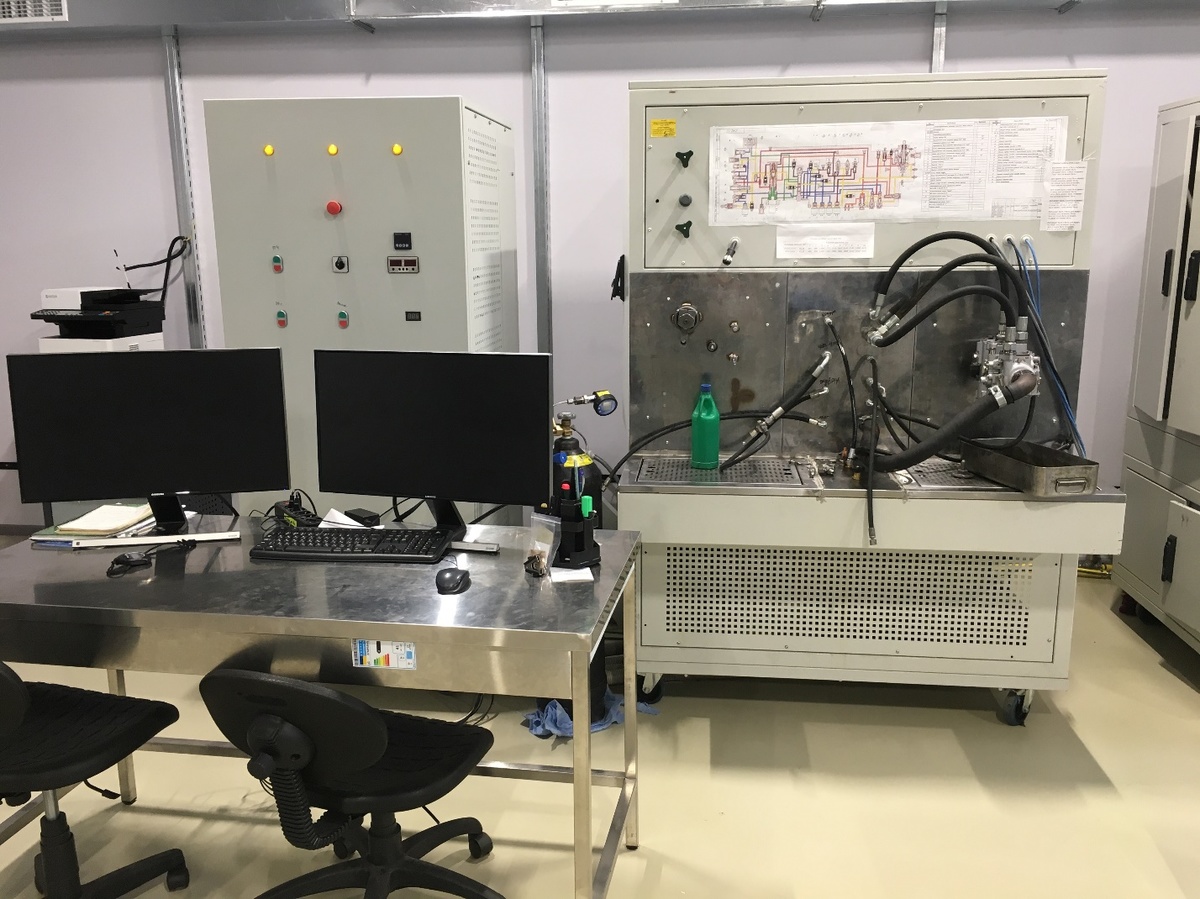

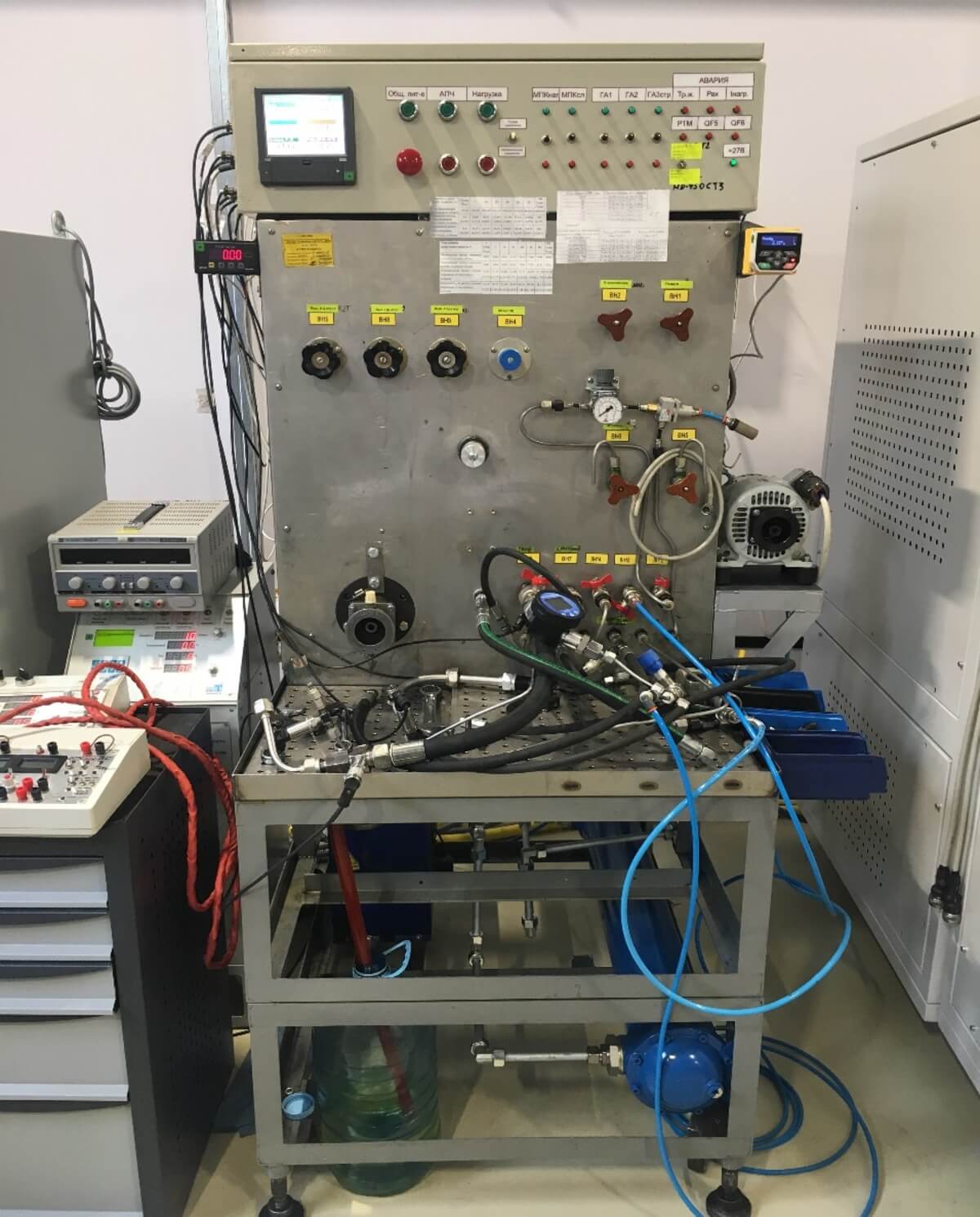

Benches are intended for running, regulation, acceptance tests, acceptance and hand-over tests and resource tests of fuel dosing pumps and rpm governors. On these benches, it is allowed to conduct testing of units with a capacity of up to 20 l/min. Power fluid: kerosene ТС-1 or its equivalent. Manufacturer: Test facility of JSC «FED».Automatic bench ValveExpert for electric hydraulic actuators on hydraulic oil Skydroll

The bench is intended for checking and adjustments of servo- and proportional valves wit a flow rare of 80 l/min and a working pressure of 210 kg/cm². The test bench is completely self-contained equipment. The operation of the bench is completely controlled by a computer system that allows to analyze quickly all the operating parameters of valves. The bench allows taking the discharge characteristic and leakage characteristic, investigating the dependence of the pressure drop at the control ports on the control signal, conducting the dynamic analysis, and doing many other things.Automatic bench ValveExpert for electric hydraulic actuators on hydraulic oil FH51

The bench is intended for checking and adjustments of servo- and proportional valves wit a flow rare of 80 l/min and a working pressure of 210 kg/cm². The test bench is completely self-contained equipment. The operation of the bench is completely controlled by a computer system that allows to analyze quickly almost all the operating parameters of valves.Bench for testing regulator pumps

Benches are intended for performing running, regulation, acceptance tests, acceptance and hand-over tests and resource tests of regulator pumps and for working with the mathematical model. On these benches, it is allowed to conduct testing of units with a capacity of up to 20 l/min. Power fluid: kerosene ТС-1 or its equivalent. Manufacturer: Test facility of JSC «FED».Bench for testing of thermal and pressure accumulators

The bench is intended for conducting hydraulic tests and cyclic tests for change of turbine-generator installation pressure. Power fluid: alcohol or distilled water. Manufacturer: Test facility of JSC «FED».Benches for running and adjusting of dosing pumps and guide vane regulators

Benches are intended for the conducting of running-in, regulation, acceptance tests, acceptance and hand-over tests and resource tests of fuel dosing pumps and rpm governors. On these benches, it is allowed to conduct testing of units with a capacity of up to 80 l/min. Power fluid: kerosene ТС-1 or its equivalent. Manufacturer: Test facility of JSC «FED».Bench for testing of hydraulic motors with variable capacity

The bench is intended for running, regulation, acceptance tests, acceptance and hand-over tests and resource tests of hydraulic motors with variable capacity. On this bench, it is allowed to conduct testing of units with a capacity of up to 3000 l/min and conduct tests with a secondary and counteraction payload of up to 400 Nm. Power fluid: FH51 or equivalent. Manufacturer: Test facility of JSC «FED».Benches for testing dosing pumps

Benches are intended for the conducting of running-in, regulation, acceptance tests, acceptance and hand-over tests of dosing pump units of various modifications and regulator pumps. It is allowed to conduct testing of units with a capacity of up to 20 l/min. Power fluid: kerosene ТС-1 or its equivalent. Manufacturer: Test facility of JSC «FED».Bench for testing units for controlling air bypass valves

The bench is intended for the conducting of running-in, regulation, acceptance tests, acceptance and hand-over tests of units for controlling air bypass valves at a high pressure up to 100 kgf/cm², as well as regulation and adjustment of position sensors. Power fluid: kerosene ТС-1 or its equivalent. Manufacturer: Test facility of JSC «FED».Bench for vacuum filling of special products

Bench is intended for vacuum filling of special products. It is allowed to create a relative pressure of up to -0.9 kg/cm² on this bench. Power fluid: hydraulic oil LZMH-2. Manufacturer: Test facility of JSC «FED».Bench for hydrostatic testing of products and units of all types and modifications with hydraulic oil FH-51

The bench is intended for hydrostatic testing of products with hydraulic oil FH-51. It is allowed to create a relative pressure of up to 700 kg/cm² on this bench. Power fluid: hydraulic oil FH-51. Manufacturer: Test facility of JSC «FED».Fuel bench

The bench is intended for flushing nozzles, valves, assemblies of regulator pumps, and other fuel products. The maximum capacity of the pump is 20 l/min, the maximum operating pressure is 100 kg/cm². Power fluid: kerosene ТS-1 or its equivalent Jet A1. Manufacturer: Test facility of JSC «FED».Bench for running in of swivel joints of regulator pumps

The bench is intended for running-in, conducting of process control of parameters and acceptance and hand over tests of of swivel joints of regulator pumps. This bench ensures testing at different speeds of the shaft drive, measuring of flow rate of up to 80 l/min, measurement of pressure of up to 100 kgf/cm². Power fluid: kerosene ТS-1 or its equivalent Jet A1. Manufacturer: Test facility of JSC «FED».Bench for testing fuel dosing valves

Benches are intended for regulating, conducting acceptance tests, acceptance and hand-over tests and resource tests of fuel dosing valve. These benches ensure running-in of process pumps, measuring pressures of up to 100 kgf/cm², measuring of flow rate in various cavities of products of up to 20 l/min. Power fluid: kerosene ТS-1 or its equivalent. Manufacturer: Test facility of JSC «FED».Thermal vacuum chamber (climatic test bench)

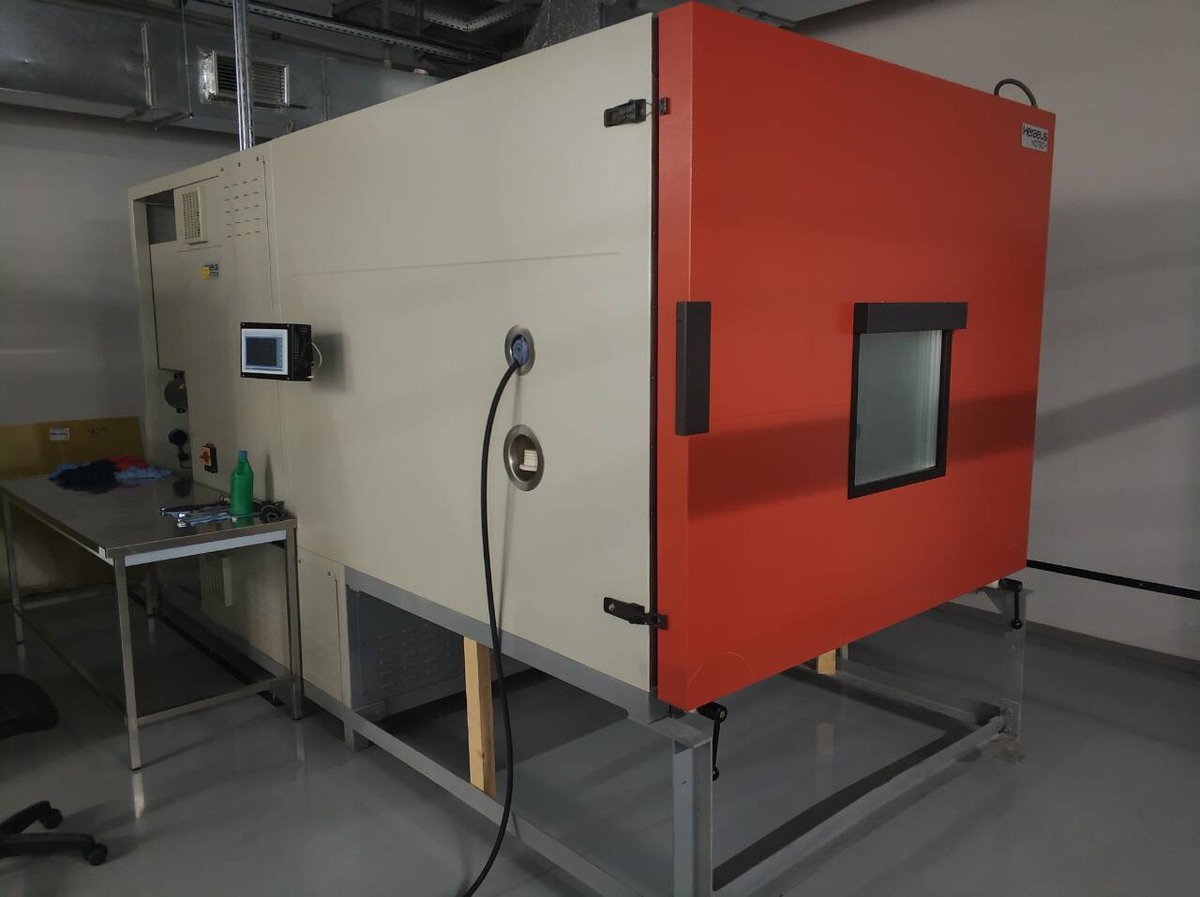

The thermal vacuum chamber simulates environmental conditions. In this thermal vacuum chamber, a variety of objects can be exposed to high and low temperatures within the range from +120 °C to -70 °C, and, in addition, in the useful volume, it is possible to apply pressure ranging from atmospheric pressure to 1.33 MPa.Thermal vacuum chamber

The thermal vacuum chamber is intended for simulating environmental conditions. In this thermal chamber, a variety of objects can be exposed to high and low temperatures within the range from +120 °C to -70 °C.Thermal vacuum chamber (climatic test bench)

The thermal vacuum chamber simulates environmental conditions. In this thermal vacuum chamber, a variety of objects can be exposed to high and low temperatures within the range from +120 °C to -70 °C, and, in addition, in the useful volume, it is possible to apply pressure ranging from atmospheric pressure to 1.33 MPa.'FED', JSC possesses:

bench for flushing valves

The bench is intended for flushing valves. Power fluid: kerosene ТS-1 or its equivalent. The bench includes the following hydraulic components: Manometers 0 ... 60 kgf/cm²; process pump Q = 25 l/min, Р = 0 ... 30 kg/cm². Manufacturer: Test facility of JSC «FED».Bench for hydrotesting of casings

The bench is intended for hydrotesting of casings. Power fluid: hydraulic oil FH51 or its equivalent АМH10. The bench includes the following hydraulic components: Manometers 0 ... 60 kgf/cm²; manual process pump Р = 0 ... 150 kgf/cm². Manufacturer: Test facility of JSC «FED».Test bench for flushing electric hydraulic actuators

The bench is intended for flushing electric hydraulic actuators. The maximum fuel consumption for flushing slide valves is 30 l/min, the maximum working pressure created by the technological pump is 250 kgf/cm². Power fluid: FH-51. Manufacturer: Test facility of JSC «FED».Bench for ensuring tightness and flushing assemblies of regulator pumps

The bench is intended for flushing assemblies of regulator pumps. It is allowed to conduct tests with the maximum capacity of the process pump of up to 30 l/min, pressure of up to 100 kgf/cm², and regulate the difference of pressures between working cavities. Power fluid: kerosene ТS-1. Manufacturer: test facility of JSC “FED”.